New building materials wholesale business established on greenfield site

Tourbosoft's logistics consulting team used precise data analysis and tailor-made ideas to plan and successfully implement a new logistics location for the building materials wholesaler Hass & Hatje.

We give you an exciting glimpse behind the scenes – from planning to reality.

“With Tourbosoft, we have an innovative consulting and software partner that has been significantly shaping our logistics for around 10 years. From the complete digitalization of our fleet logistics to complex location planning and site expansion, Tourbosoft's comprehensive expertise has won us over.”

Ralf Lüthje, Managing Director of Hass + Hatje GmbH

____________________

Building materials retailer Hass + Hatje plans new wholesale location in Bad Segeberg

Hass + Hatje GmbH has established itself as one of the leading suppliers in the building materials trade and now occupies a leading position in the region north of Hamburg.

After acquiring a plot of land for the relocation of its wholesale business in Bad Segeberg, the building materials supplier commissioned Tourbosoft's logistics consultancy to develop a logistics concept for this new location.

The goal was to design the logistics for the warehouse and loading buildings as well as the outdoor storage areas and traffic routes. The concept covers material flows, equipment technology, and processes for goods receipt, storage, order picking, loading, customer service for self-collectors, traffic management, as well as administrative and scheduling processes. The plan was based on medium-term sales growth of 45% for self-collectors and 55% for deliveries with the company's own fleet in Bad Segeberg.

From logistics planning to reality: a new location for the building materials wholesaler is emerging

1

Data as the architect of success: logistics planning based on comprehensive analyses

As logistics planners, we consistently rely on data as an indispensable basis for our recommendations. Instead of relying on vague assumptions or planning blindly, we anchor our strategies in precise analyses. This data-driven approach enables us to develop logistics solutions that not only look good on paper, but also stand up to reality.

Therefore, our analysis for Hass & Hatje began with the sales figures for Bad Segeberg and Bad Oldesloe, which were broken down in detail by product segment, such as building and civil engineering materials, landscaping, plumbing, wood, doors, and floor coverings. We placed particular emphasis on distinguishing between stock items and commission goods, as well as delivery and self-collection. This differentiated approach enabled a comprehensive understanding of the initial situation, which in turn created the basis for precise planning and reliable results.

We then focused on the daily throughput in each category and analyzed the main delivery areas for both locations. The focus here was on the distribution and overlap of customer areas. An accurate assessment of inventory levels was carried out in order to determine a meaningful inventory turnover rate for each product group. We paid particular attention to data on self-collectors, including daily orders, their distribution throughout the day, and seasonal fluctuations over the course of the year.

The current vehicle fleet and forklifts in the warehouse were examined in terms of their suitability and number in relation to the requirements. At the same time, we analyzed the logistics staff structure, calculated the turnover per employee, and compared it with industry standards. In addition, the property was examined closely, focusing on the available space and its logistical uses.

The current vehicle fleet and forklifts in the warehouse were examined in terms of their suitability and number in relation to the requirements. At the same time, we analyzed the logistics staff structure, calculated the turnover per employee, and compared it with industry standards. In addition, the property was examined closely, focusing on the available space and its logistical uses.

2

Strategic logistics planning: Tailor-made site design for efficient operational processes

When planning the detailed layout of the site, we focused on carefully calculating the future space requirements. This was based not only on current sales figures, but also on target sales and position throughput.

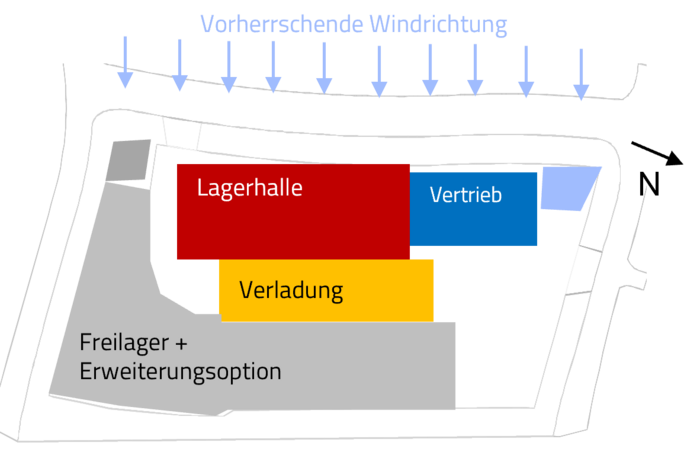

Particular attention was paid to ensuring optimal hall widths and dimensions as well as protecting the loading zone from driving rain, especially given the unstable weather conditions in northern Germany. We also took into account the size of contiguous hall areas, efficient contact between the loading zone, hall, and open storage area, and the possibility of future expansion of the sales building.

Within this framework, we developed different layout options for the property design, taking a holistic view of the warehouse, sales building, exhibition area, loading zone, and traffic flows. In particular, the focus was on minimizing contact between heavy goods traffic and customers picking up goods.

In the following section, we will take a closer look at the design of the pick-up and loading zones as well as the traffic flows, which must ensure well-thought-out and efficient operations.

3

Logistics in flow: Well-thought-out design of traffic routes in the pick-up and loading zone

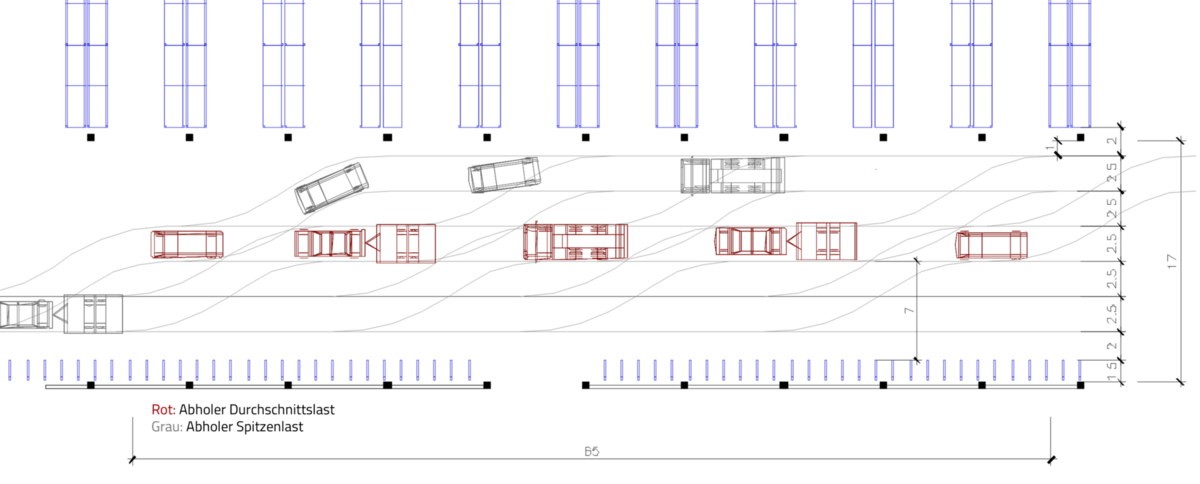

The detailed design of the pick-up and loading zone was the focus of our considerations. Particular attention was paid to the clear separation between truck loading and pick-up by self-collectors, as well as the well-thought-out design of their respective traffic flows.

We carefully considered how many lanes would be needed to ensure smooth passage for pick-up customers along the loading zone while also allowing them to leave the premises without any problems, even in the event of possible traffic jams. The number and orientation of the parking lanes played a key role in this.

Special attention was paid to truck loading, where the design of the road width was crucial to ensure that at least two trucks could be loaded side by side at the same time.

Our analysis also covered the necessary routes for internal warehouse traffic. Not only were intersections with forklift traffic and exits from the hall taken into account in order to minimize the risk of accidents, but also the safe maneuvering of forklifts was ensured.

Tourbsoft's plans become reality: Construction of the new Hass & Hatje building materials store

The solution developed is a tailor-made response to the logistical requirements of the Hass & Hatje site. It not only meets current needs, but also lays the foundation for future growth. The vision that was once sketched out has now taken concrete shape. We at Tourbosoft are delighted to see how the plans implemented by our logistics consultants have come to life. This is a fine example of how careful planning paves the way for efficient logistics processes.

Arrange a free consultation with an expert

Discover the potential of efficient and optimized logistics for your company and contact us for customized logistics consulting! Our team looks forward to supporting you with a free expert consultation.